Because they are the most economical solution for your safe packaging needs to equalize pressure difference that can cause containers carrying liquids to deform, leak or sometimes causing it to burst.

Vented Products

Why use Vented Products?

Such defects can have a negative impact on the image of the brand, ultimately denting the customer relations and profits of the company, and adding to the expenses.

Such defects can have a negative impact on the image of the brand, ultimately denting the customer relations and profits of the company, and adding to the expenses.

Trying to find and solve the packaging problem can be time consuming and expensive. In the end problem may not be resolved completely and customer satisfaction is also doubtful.

Trying to find and solve the packaging problem can be time consuming and expensive. In the end problem may not be resolved completely and customer satisfaction is also doubtful.

If dangerous liquids are leaked they can have great risk to end-users and environment. Clean up cost of the same is also huge.

If dangerous liquids are leaked they can have great risk to end-users and environment. Clean up cost of the same is also huge.

Causes of Containers/Bottles Deforming

Releasing and Consuming Gases

Certain active ingredients release gases in the containers. If these gases can’t escape, the container will bloat, leak or even burst in some cases. While some active ingredients consume oxygen leading to the drop of pressure in the container. This can result in collapsing of the container.

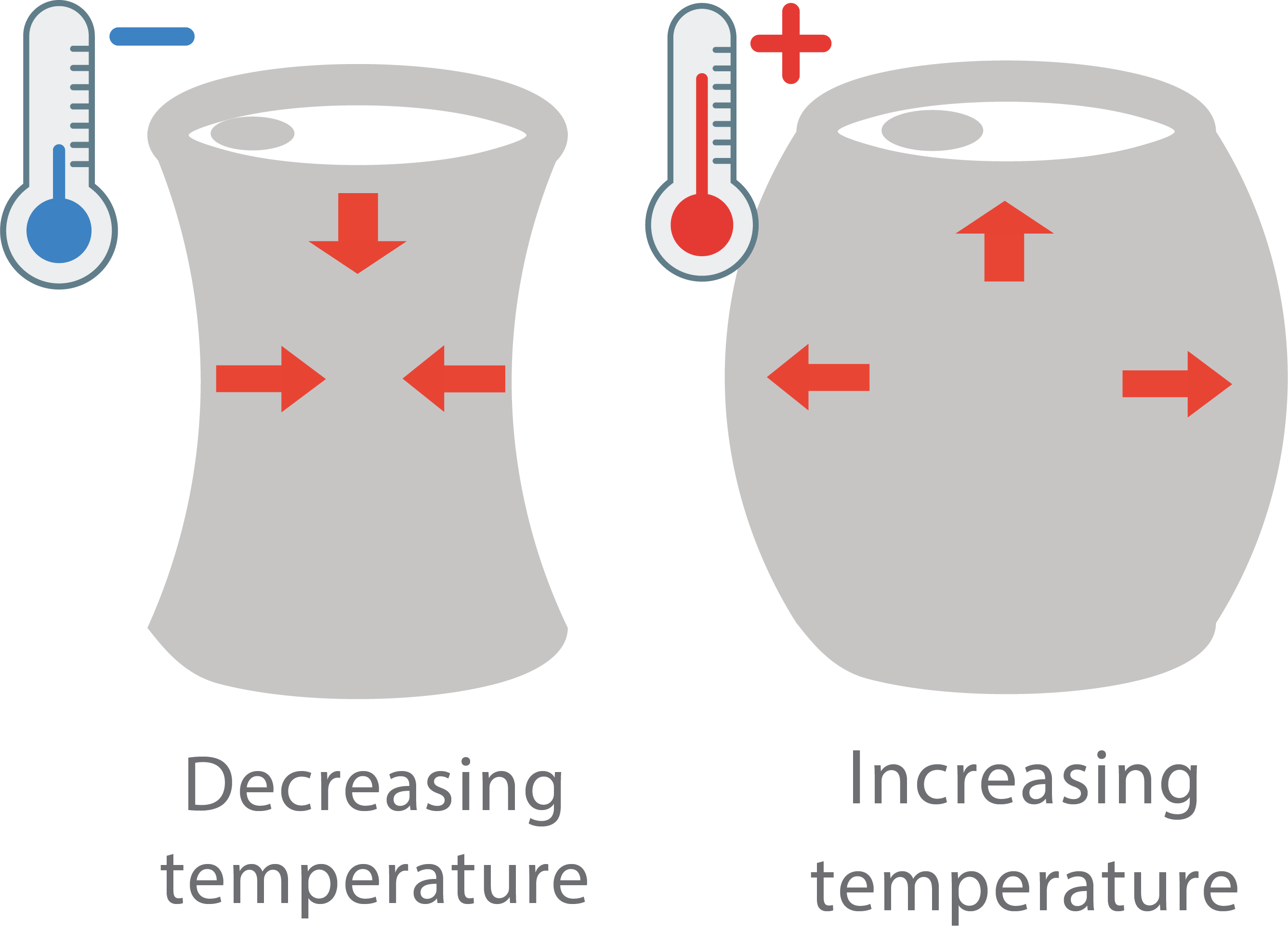

Temperature Changes

Change in temperature or exposure to different climate conditions also deforms the containers. Rise in temperature expands gases in the headspace of containers and increases rate of decomposition of reactive chemicals. This can result in bloating of containers. Decrease in temperature can reduce pressure in containers and can lead to collapsing of them. Sudden changes in temperature can accelerate these processes.

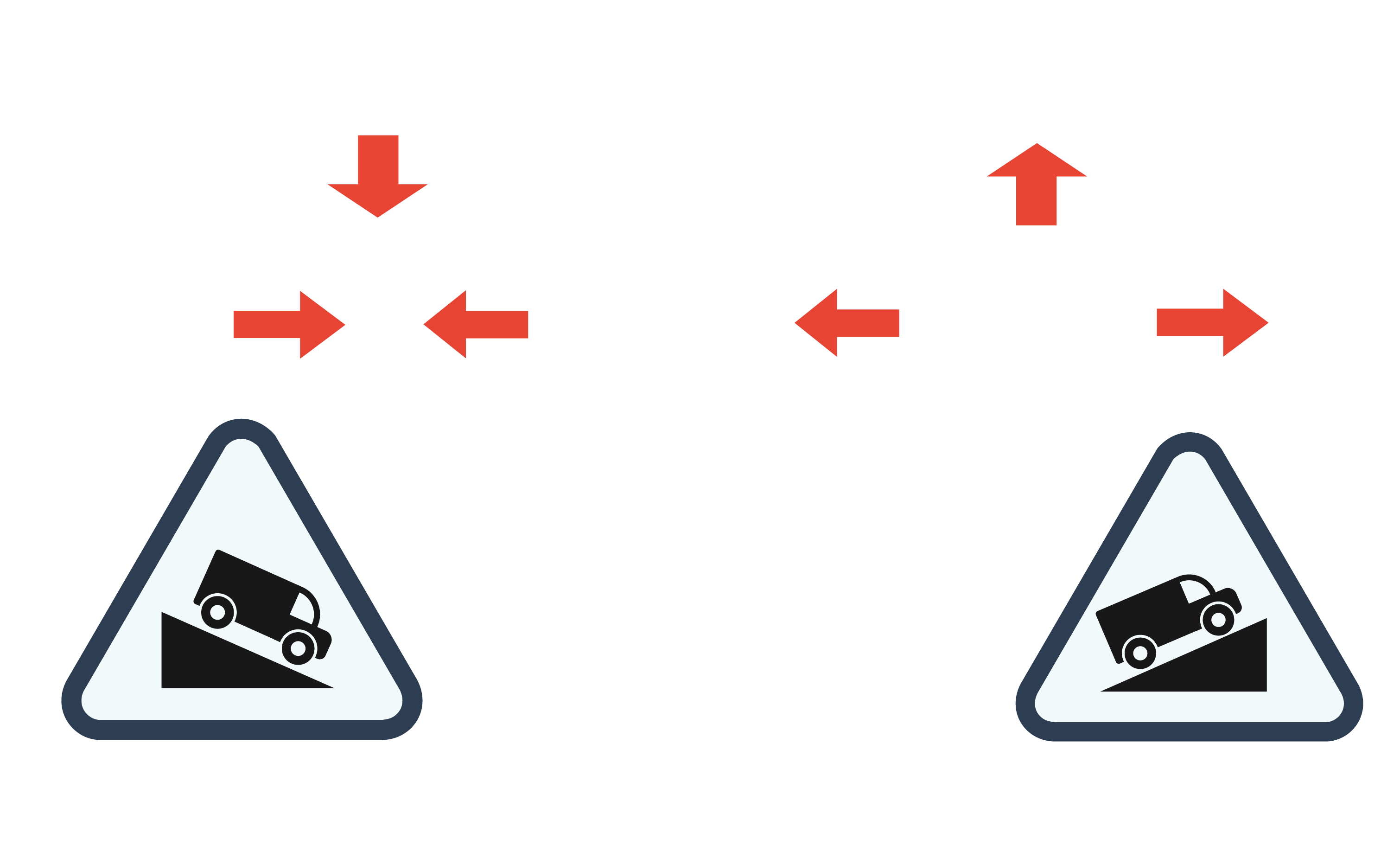

Altitude Changes

Change in altitude during transportation creates differences in pressure between the containers and surrounding. Increase in altitude creates over pressure in the container which can result in bloating. Decrease in altitude creates under pressure in the container resulting in collapsing of container. Sudden or extreme changes in altitude accelerate these deformations of containers.

Applications

Hazardous Chemicals & Institutional Cleaners

These chemicals tend to off-gas or absorb gas resulting in container deforming. It is highly recommended to use vented product for their safe packing. Containers carrying these chemicals require pressure equalization:

Peroxides, disinfectants, peracetic acid and chlorine bleach.

Agrochemicals

Use of vented products to let some pesticide and fertilizer containers breathe is highly recommended as their deformations and leakage can lead to damaging of label, foul smell in the surrounding and negative impact on the brand value. These agrochemicals require venting: Pesticides,insecticides, fungicides and organic/inorganic fertilizers.

Household Chemicals

With the increase in use of complex formulation for household chemicals, unvented packaging of same can result in deforming and leaking. There is very high probability of such deformed, leaked and label damaged containers will be rejected by customer. These products require venting for safe packaging: Laundry detergents, carpet cleaners, surface cleaners containing chlorine and bleach or chlorine and ammonia.

Why Choose Us?

All our products are manufactured at our facility, saving us from having to rely on others. They also go through airflow and leakage testing before leaving our factory. This enables us to deliver high quality products with great performance. Apart from this we have the widest range of vented products and all our products are tested and widely accepted by packaging industry.

The products can be customized as per client’s packaging requirement for airflow, type of membrane, and other parameters. Developing new products also come handy with our own workshop for making mold.

Benefits of using vented products

Vented products are the most economical solutions for your safe and reliable packaging needs.

- Easy installation that can be used with most of the caps, closures and containers

- Consistently high airflow preventing deforming and leaking of containers

- Excellent liquid resistance and prevent liquid penetration

- Continue to vent even after exposure to liquids containing organics, surfactants, oils and solvent-based liquids